These are double or single handled tools designed to remove more wood than planes and less than an ax. In some cases these are the roughing tools used to get pieces of wood to their desired rough shape. In other cases these tools are used for the final finish work and no further smoothing is required.

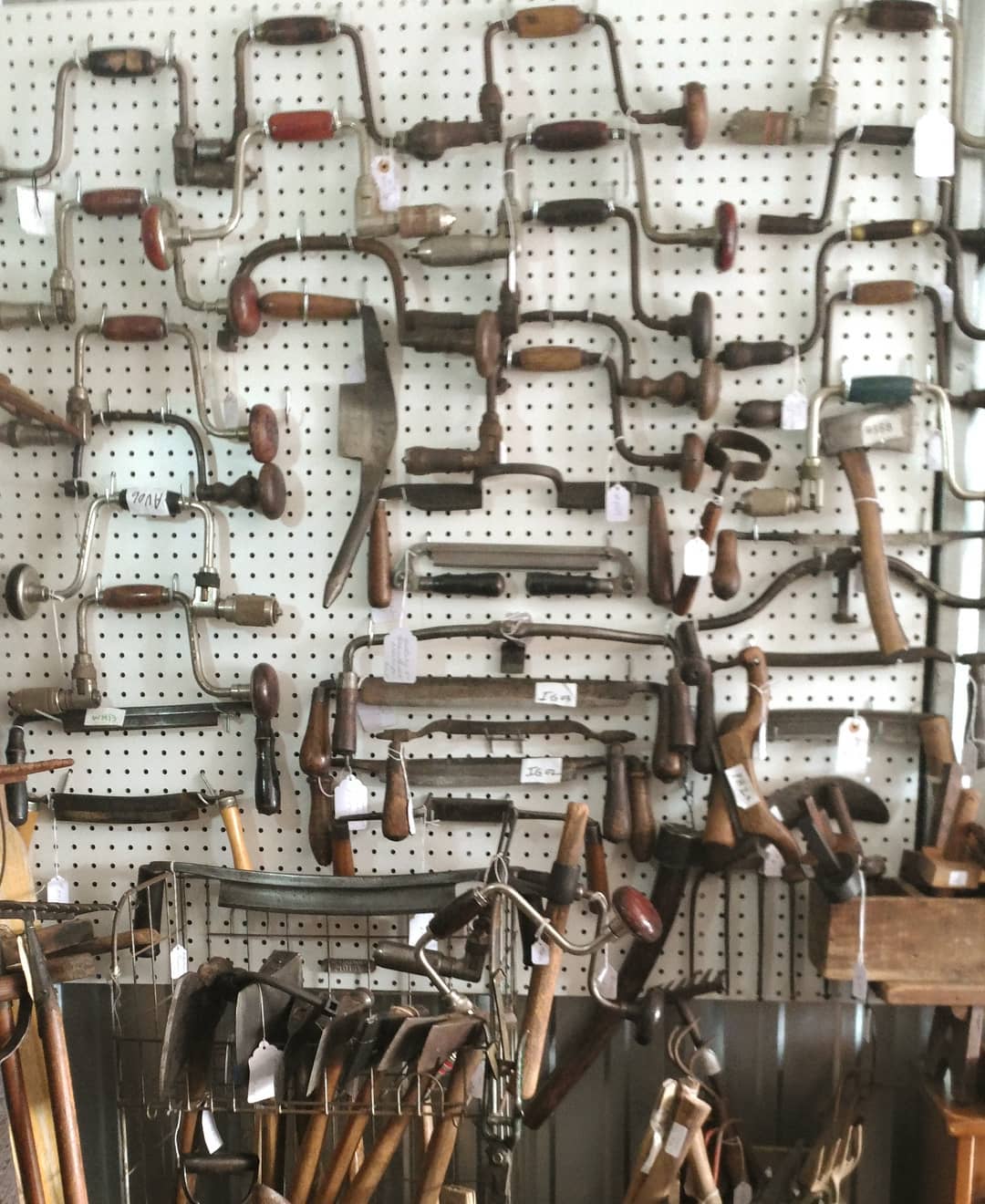

Drawknife is the classic roughing tool that gives more control than the ax. The drawknife is a wide U shaped tool with wooden handles on each leg and a steel blade in between. American versions usually have longer turned cylinder shaped wooden handles while European have spherical shaped handles. In almost all cases the tangs on each end of the drawknife are bent or clinched over on the ends of the drilled handles. Some are reinforced with washers on the clinched, riveted or peen ends and some have ferrules at the other end to prevent splitting. This tool is grasped with both hands and pulled towards you. Pulling a long sharp blade directly toward yourself can be a bit intimidating at first and you should use caution when working with this tool. The tool is usually used with the bevel facing up, but in some circumstances of difficult grain or shape the tool can be used bevel down. This is useful for working inside curves with flat bladed drawknives. These tools have flat blades but most have a gentle sweep to the blade. They can be used perpendicular to the grain of the wood but holding them on a skew angle to the wood will make it cut easier as with all edge work. Also work with the grain of the wood see illustration above for proper orientation. Because it doesn’t have a mouth like a plane or spokeshave, the drawknife can dig in deep to the wood so care must be exercised when using this tool to prevent if from cutting too deep. Folding handles on drawknives were introduced in the mid to late nineteenth century. With bolts and wing nuts the handles could be folded against the blade to offer some protection to the blade as well as making them easy to transport.

Scorp is similar to the inshave but has only one handle. The tangs on each end are shaped to fit in one handle, are smaller than the inshave and used for lighter duty wood removal in bowls, seat bottoms and other hollowed work. Because of the smaller size the scorp can make deeper cuts and is easy to turn to deal with changes in grain direction. When cutting at the bottom of an excavation in wood the grain converges and presents a problem. When it starts going up the other side the grain dives into the wood and will chip and split out. If you use the scorp at 90º to the grain at the bottom it will finish of this difficult area. Using the tool on a skew can also facilitate easier cutting.

Jigger is a combination drawknife and inshave. The tool is identical to the drawknife except part of the blade is usually bent into a convex curve and part of the blade is straight. This allows the worker to change from flat to hollowing cuts without changing from a drawknife to a scorp or inshave. Coopers use this tool for rough shaping the ends of the barrel and can be used to make the chime and the howel. A Jigger can be a cost saving tool as it incorporates a drawknife and an inshave all in one tool.

Inshave is a tool similar to a drawknife with a deep bent blade and is used for hollowing out seat bottoms, trenchers and large bowls; anywhere depressions in wood are required. The offset handles and curved blade gives excellent control over wood removal. The tool is usually used with the grain but on certain woods and cuts it is used cross grain. The depth of the bend blade and the length of the handles are important to consider. I once saw an old inshave that had very little wear on such an old tool. The answer was the fact that the blade and handles were of such length and angle to make the handles hit the work before the blade could engage the wood. It looked good, but it had never been used.

Coach maker’s Router comes in two forms the first in wood and the other in metal. The metal version of this tool looks like a drawknife in overall shape but has small (sometimes interchangeable) cutting irons. These tools are used to make grooves in the curved framework to receive the panels common in coachwork. They are also used to bottom out the recesses and mortices to receive the ironwork that is let into the wooden framework. With the handles positioned the way they are the cutter can be easily controlled but lacks a depth stop that some of the wooden versions have. A little tricky to use but once you get the feel of the tool it can be a very handy and useful tool. See Making and Using a Router for a discussion on Wooden Coach Maker’s Router.

Shaving Horse or shaving bench is a tool used to hold work while using a drawknife, spokeshave and other hand tools. This tool has a place to sit, a ramp to hold the work and a head that holds the work to the ramp. The head or jaw is actuated by a foot lever and by pressing down with your foot; the work is clamped to the ramp securely and can be easily worked and repositioned. The jaw and all edges are rounded on their sharp corners to prevent them from marring the work being held. The shaft from the jaw to the foot pedal has holes drilled in different locations along its upper length to make it adjustable for different thickness of wood. It can also be adjusted along the length of the ramp to position it where it is needed. Work is usually done towards the worker and pressure on the foot pedal will force the jaw to pivot and hold the work to the ramp. The work can be easily repositioned easily by releasing foot pressure and moving the work to a new surface to be tooled. Longer pieces can be held with the length running down the ramp by either side of the shaft. The Jaw should be as wide as the ramp; if it is narrower it can be difficult to get up close to the edge, if it is wider than the ramp it also gets in the way. When I build a shaving horse I make it so that the jaw with open naturally by gravity. There also designs using wooden springs to open the heavy head of some shaving horses. While this is not necessary, it is very handy if the jaw will open up by just releasing pressure on the foot pedal.

Handle or Spoke Vice is a tool similar to a bar clamp or a lathe, that is used to hold tool handles or spokes while they are being shaped. There are two metal center points one in a fixed head, the other in an adjustable head that holds the work. These vices are secured to a bench or convenient location and adjusted to the approximate size of the work. A threaded metal center point on one head is adjustable to tighten against the center of the end of the stuff being worked. The work can be turned by hand to a side that hasn’t been worked yet, the threaded center is tightened and the work is at a good height and place to work with the above tools. When doing repetitive work this is a handy tool for holding pieces at a convenient height to easily work. The work can be turned to expose a new side to work and continued around until the piece is finished. The open exposure of the work when held in this clamp or vice is indispensable for shaping, carving and countless other applications. Can also be used to hold a pattern that is being reproduced on a turning lathe.